Concrete Technology Research Papers

Concrete Technology Research papers are mainly deals with the best research on the materials science and engineering of cement, cement composites, and more.

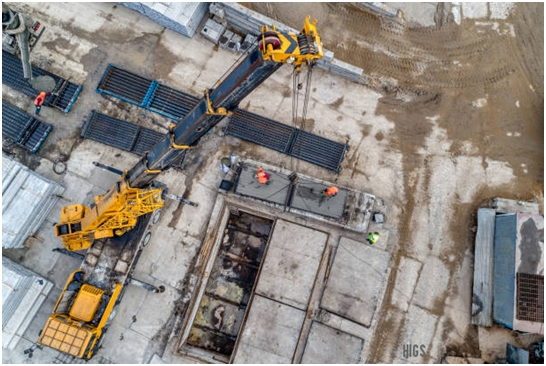

The field of Concrete technology deals with the study of concrete properties and their practical usages and practices.In building construction, concrete is the core material, it is utilized for the foundation construction, beams, columns, slabs, and other weight-bearing components. There are variouskinds of the binding material is utilized other than cement for example lime for lime concrete and bitumen for asphalt concrete that is used for road construction.

Components of concrete:

Here, we have given some of the components of concrete. They are sand, cement, aggregates, and water. The paste is actually a mixture of Portland cement and water. Thus, concrete will be known as a mixture of paste, sand, and aggregates. Sometimes rocks are utilized instead of aggregates.

The surface will be coated with cement paste and coarse aggregates will bind them when mixed thoroughly. Soon after mixing the components, hydration reaction will beginand offers strength and rock-solid concrete is attained.

What is Concrete?

Cement, a filler (such as sand or gravel), water, and customary admixtures are combined to make the composite material known as concrete. And the concrete

machine is used to create concrete, a concrete mixer also known as a cement mixer, and it is homogeneously mixes cement, aggregate such as sand or gravel,

and water.